Tesla Background

Tesla, Inc., an American company. Martin Eberhard and Marc Tarpenning were the brilliant minds behind Tesla Motors which was assimilated on July 1st, 2003. The third employee of the company was Ian Wright and later on, Elon Musk joined the company and became the chairman of the board of directors. Later in 2004 Jeffrey Brian Straubel also joined Tesla. Eberhard, Tarpenning, Musk, Wright, and Straubel are known as co-founders in 2009. Palo Alto, United States, and California are the headquarters of Tesla. Tesla offers products like electric cars, solar panels, batteries, etc.

Company’s Incentive

Its motive is to speed up the world’s transformation to sustainable energy by finding renewable energy sources. The engineers of Tesla wanted to prove that electric cars can be more than that car that runs on gasoline.

Tesla’s Current Statistics

Tesla is one of the leading brands of electric vehicles globally. In 2020, it delivered 500,000 units of its vehicle, and its new model, Model 3 is one of the best-selling electric vehicles. Tesla’s net revenue is 31.5 Billion US dollars. The quarterly vehicle delivery of Tesla is about 185k.

Tesla has endured its supply chain and value chain satisfactorily. The biggest market for Tesla is China where the demand for Tesla is still rising. The company is making the value chain analysis effective to attain profitability.

Value Chain Analysis

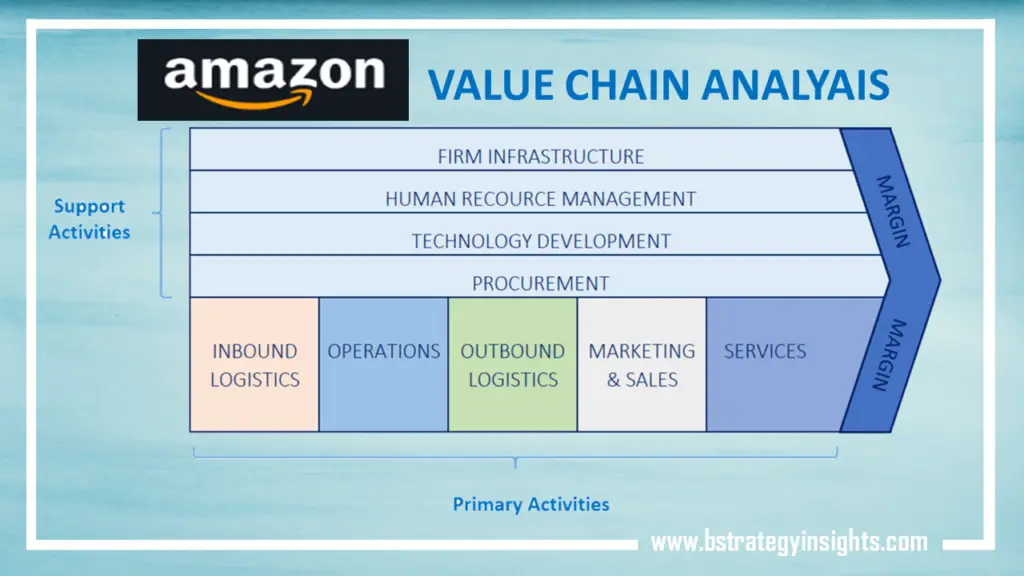

The concept of Value Chain was originally put on by Michael E. Porter. This concept comprises all the activities such as purchasing raw material, storage, handling, production, marketing, distribution, and post-marketing management. The individual activity in this adds up the value to the product. Analysis of these activities or value chains can provide remarkable results. By increasing the efficiency through the value chain the company can optimize the operations. The value Chain includes two categories of activities particularly primary and supportive activities.

Primary Activities

Primary activities in Porter’s value chain refers to the production and services. The primary activities of a firm include inbound logistics, outbound logistics, operations, sales and marketing, and lastly services.

Inbound logistics

Inbound logistics imply the succession of goods into the company including storage, delivery, and transport. In the United States, there are a large number of Tesla warehouses. One of these is also situated in Taiwan. The United States, California, and Fremont are the countries where the main assembly of the Tesla occurs. These conveniences can be used for manufacturing and as well as for the warehouse. 5.5 Million sq. ft. is the estimated size of the warehouse (not including other warehouses) which can be used for delivery and storage as well.

The main locations of the Tesla warehouses are Livermore, Lathrop (both in California), Taipei City in Taiwan, Sparks Nevada, Bethlehem in Pennsylvania, and Elkridge in Maryland.

Tesla Operations

The dream of making electric mobility for everyone became possible by the strong efforts of a group of engineers in 2003.

The roadster was the first highway legal serial electric car production and the first generation of Tesla launched in 2008. Then later after the strong contribution, they launched their second model named Model S. The headquarters of Tesla is located in the United States, California, and Palo Alto.

Nevertheless, the business became larger after the expansion of operations to other countries around the world, mainly China. The final assembly of the cars occurs in Tilburg. European Union receives the quality assurance of the Model X and Model S. The energy storage products and the vehicles, Model 3 are made in gigafactory 1 which is situated in Nevada. Gigafactory 2 and gigafactory 3 are located in New York and China respectively.

Tesla Outbound Logistics

In Tesla’s manufacturing network the biggest and leading facility for manufacturing is located in Nevada. Final assembly and the testing after manufacturing occur in California. distribution operations occur in Tilburg and many warehouses are also located in the US. The demand for Model 3 has been made Chinese by Tesla.

Tesla Marketing and Sales

There is a large competition between the automobile companies and they work through digital media or media to promote their brand. Many companies have invested a lot of money in the marketing of their brand while Tesla is the company that invested a minor amount in marketing than other companies in the business. It invested in marketing mainly on its website and other digital channels. Most fans of Tesla are also engaged on Twitter with Elon Musk.

That has made many stores globally that are used for the promotion and marketing of their brand. Services are also being provided in these stores. This love can also get faster feedback from their customers through these stores.

Services

Cybertruck is the new innovative creation of Tesla; it mostly looks like a sci-fi truck. It is a powerful truck and also environment friendly. The company launches many other energy storage products and vehicles. But rooster is the first generation of Tesla that was assembled in 2008 and later it also launched Model S. In 2015 the company announced model X and in 2016 model 3 was launched so model 3, model X model Y, Roadster, and Cybertruck are Tesla’s energy products. There are retail stores and service stations that are located in numerous regions which contribute to after-sales assistance to the customers.

Supportive activities

Supportive activities are the activities that are linked with the primary activities and provide assistance to the primary activities to run the functions of the organization.

Supported activities of Tesla include technology development, the infrastructure of the company, Human Resource Management, and procurement.

Technology development

The world’s wild electric mobility Industries can only be differentiated from each other from Technology till now the automobile industry has evolved a lot. BMW is the main opponent of Tesla till now BMW has also launched their electric vehicles and they are committed to expanding their electric vehicles in the industry. Dominantly measuring Technology and electric mobiles at the latest and breaking Technology in the automobile industries. Ratlam is heading in the area of development and research. In 2018 the Tesla company was financed 1.46 billion dollars for the study and advancement. As compared to last year Tesla has invested 6% more in the Research and Development Department helping Tesla grow its demand.

The Firm Infrastructure of Tesla

Based on their products they are organized into two main categories of division such as energy production division and automobile sector. The Administrative structure of Tesla is as follows

- Alan mask is at the top and he makes the main decision of the company

- Zachary J. Krikhorn who is responsible for the financial And accounting department

- Whereas the vice president of Tesla leads the other numerous opinions that are required in sales, Production, etc.

Human Resource management of Tesla

For running the organization and maintaining profitability the human resource management is very important. HR management can be ascertained to increase the competitive strength of its opponents and it can make the company competitive. Tesla is granting significance to the HR department to strengthen its relationship with the customer and ultimately to increase its strength

Procurement of Tesla

Catla has thousands of suppliers globally and has made a good relationship with them. There are many key parts or raw materials that can be obtained from suppliers and for that intention, Tesla has built an active relationship with their suppliers. One of the best suppliers of tesla is Panasonic.

Conclusion

By the method of value chain analysis, Tesla Motors can purchase quality raw material and broaden customer devotion based on the validity that Tesla can achieve competitive differentiation by shortening the delivery time of the ordered products to clients. The further approach can also be utilized by Tesla Motors to develop its human resource methods. It promotes the value chain activities to inaugurate improved customer assistance.